-

Products

- Type 1 to Type 2

- Type 2 to Type 2

- Type 1 Tethered Cable

- Type 2 Tethered Cable

- Tesla Charging Cable

- Read More

- Type 1 to Type 2

- Type 2 to Type 2

- Type 2 to Type 1

- Type 2 to GBT

- Tesla to J1772

- Read More

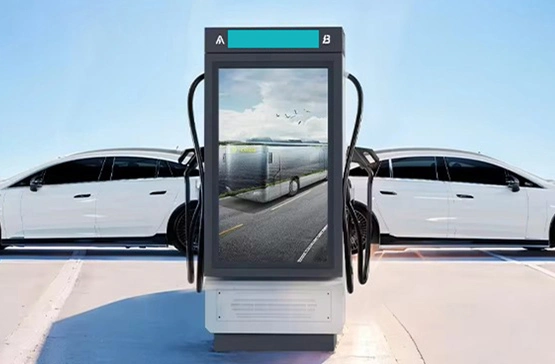

- 60kW 90kW 120kW DC Charger Pile Advertising Screen Floor Mounted EV Charging Station

- GBT CCS1 CCS2 NACS CHAdeMO EV DC Charging Station 60kW-120 kW With OCPP1.6J

- 60kW 90kW 120kW DC Charging Station OCPP1.6 Floor Mounted Advertising EV Charging Station 55 inch screen

- 40kW-240kW Fast DC EV Charger with 2 CCS1 CCS2 CHAdeMO NACS GB/T Cables

- OCPP DC Fast EV Charger 60-240kW Commercial CHAdeMO CCS2 Dual Port Smart Ev Charging Station

- Customized 60kW 90kW 120kW 160kW 180kW 240kW Dual Gun CCS2 CHAdeMo GB/T Fast Charging Station

- 60kW 80kW 120kW 160kW 180kW 240kW CCS1 CCS2 GBT CHAdeMo DC EV Charging Station

- IEC 62196 Type 2 Female EV Charging Socket 1/3phase 16A/32A Type 2 EV Socket

- IEC 62196-2 EV Charger 32Amp 3 Phase Type 2 Female EV Connector Socket for Wallbox

- Type2 EVSE IEC 62196-2 Connector Socket Plug Mount AC Dummy Station

- 16A 32A IEC 62196 Type 2 EV Charger Socket With Shutter

- 16A 32A 3 Phase IEC62196-2 Type 2 Outlet Sockets with Solenoid Lock and Shutter

- Solutions

- Resources

-

OEM EV Charger

-

Services

- About Us

- Blog